Finned tube rolling mills (HPRT)

Finned tubes are used in heat exchangers for various purposes in technological processes of the oil refining, petrochemical, gas and other industries. Finned tubes are produced on cross-helical rolling mills of the HPRT model. HPRT mills are classified by the size of the supporting tube for rolling finned tubes HPRT 12-25, HPRT 22(25)-40. Cross-helical rolling mill for finned tubes is designed for cold rolling of finned mono- and bi-metallic tubes with solid helical finning used in heat exchangers. The initial shell for rolling is a mono- or bi-metallic tube. The bimetallic shell consists of a supporting tube (steel) and a finned tube (aluminum), put on the supporting tube and fixed on it with one end, which is fed into rolls. The bimetallic pipe is assembled outside the mill equipment in a special section that is not included in the delivery package.

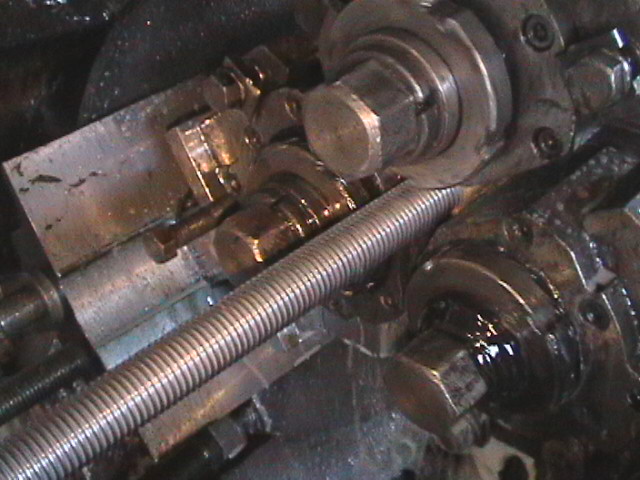

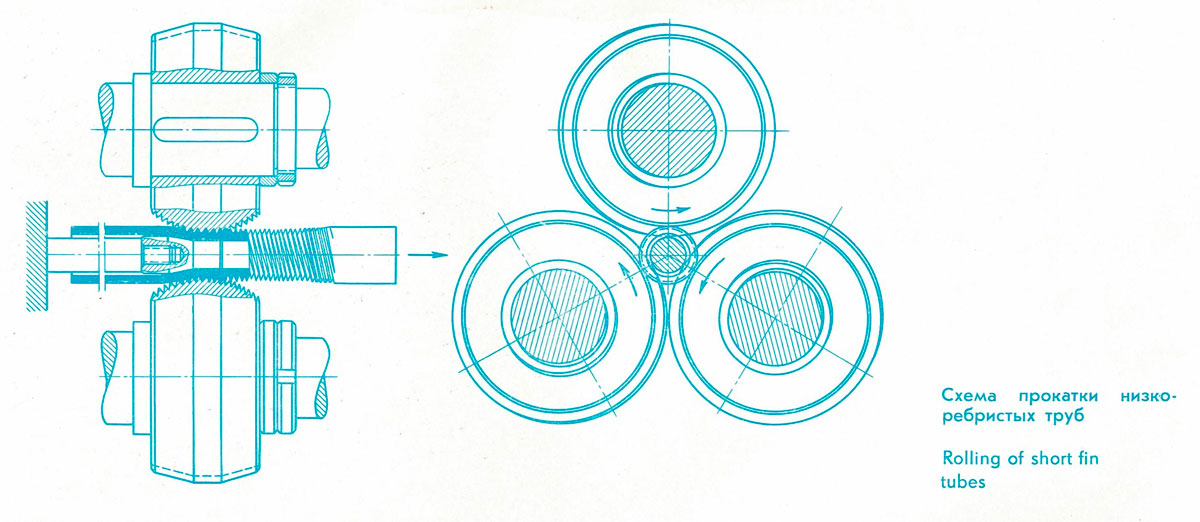

The composition of the mill equipment is determined by the adopted rolling process, the method of feeding the shell into the working stand, and the mechanization of auxiliary operations on the mill. Rolling of bimetallic ribbed tubes is carried out using the transverse helical rolling method in a three-rolls stand. During rolling, a lubricating and cooling liquid is supplied to the deformation zone. Auxiliary operations on the mill entry side ensure individual feed of shell to the rolling axis, unwinding of the coil while simultaneously loading it into the rolls of the working stand. On the mill exit side, auxiliary operations move the ribbed tube after rolling into the receiving chute and dump it onto the rack conveyor. The operations of transporting shells to the mill entry side, individual feed of them into the feed rollers, and removal of ribbed tubes from the rack conveyor are carried out by additional means.

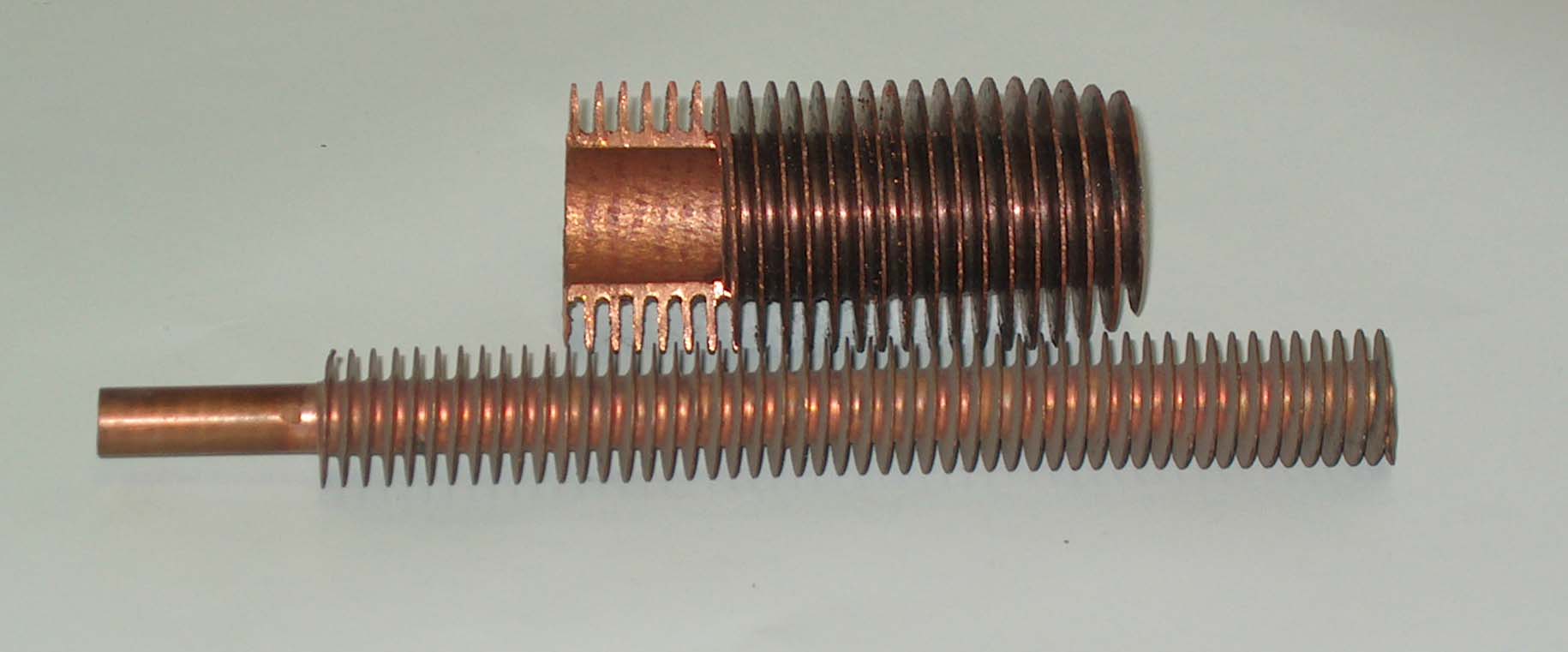

Depending on the operating conditions, either high-finned or low-finned tubes are used. In high-finned tubes the fin ratio (the ratio of external to internal surfaces) reaches 16, ranging from 2.5 to 4.0 in tubes with short fins. Finned tubes are manufactured from aluminium, copper, mild steel and alloys, or from bimetal stock: brass-aluminium, copper-aluminium, steel-aluminium, etc.

Finned tubes are rolled from plain tube serving as shells. Bimetallic finned tubes are rolled from plain tubes fitted one over another, solid joining being obtained on rolling. Tubes with high fins are manufactured in standard (5-6m) and non-standard (from coil) lengths; tubes with short fins are rolled in standard lengths and with finless ends for connection to tube plates.

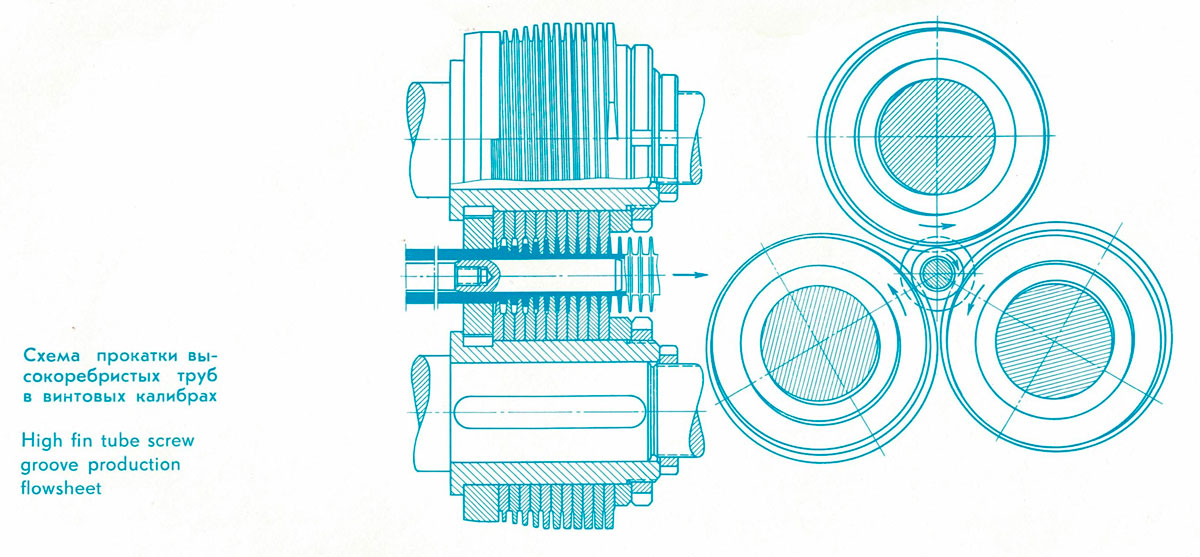

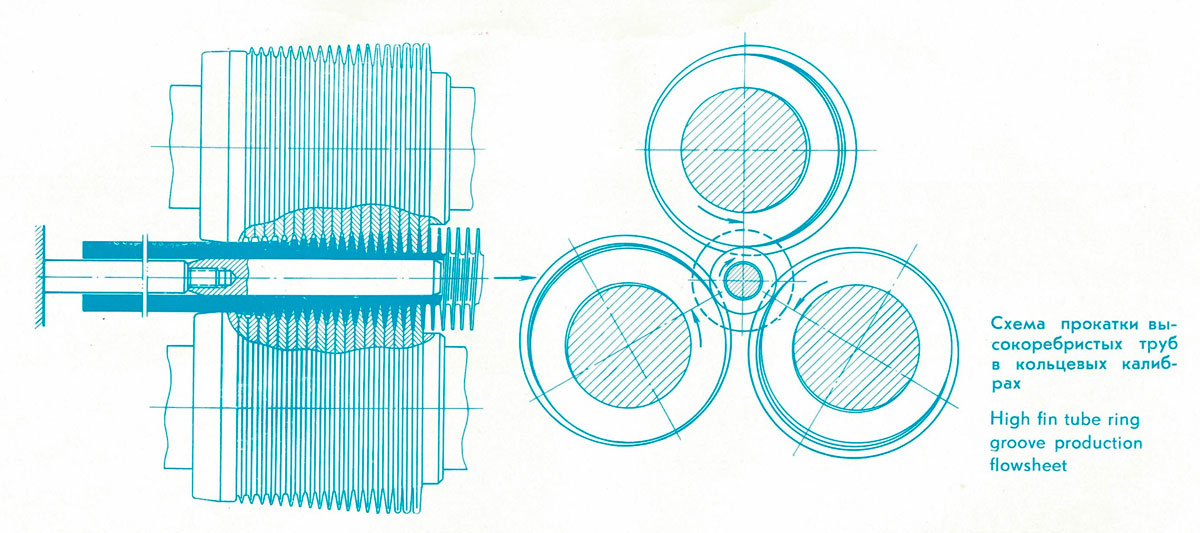

Finned tubes are produced in three-roll helical rolling mills. Finned tube is formed on a mandrel by three driving rolls, the axis of which are at an angle to the axis of rolling. The rolls grip the shell, imparting to it rotation and axial travel, with the effect that fins are fashioned to desire shape and the tube is taken off the mandrel. A finished tube is obtained in a single pass.

Two type of rolls are used: one, with ring, the other, with screw grooves. The ring groove is used to produce high fin tubes with single- and multi-thread fins, the fin pitch ranging from 1,5 to 6 mm; the screw groove - for high ring or screw fins with a pitch in excess of 6 mm. Rolls for producing short fin tubes are usually made solid. Their surface is ring- or screw-threaded in a profile negative with respect of that to a finished tube.